Blank Welder Performance Qualification Record PDF Form

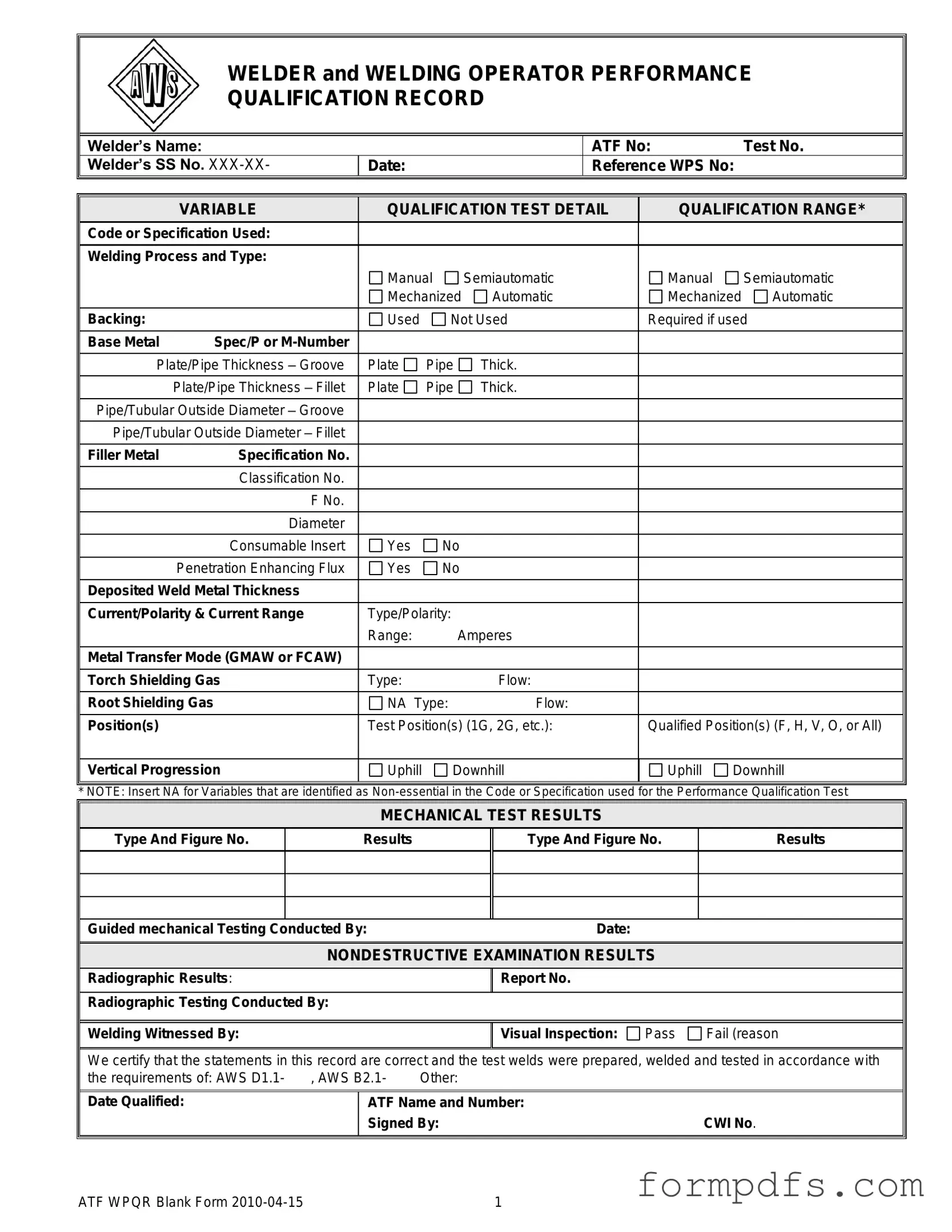

The Welder Performance Qualification Record (WPQR) form is an essential document that verifies a welder's skills and qualifications in various welding processes. This record captures vital information, including the welder's name, identification numbers, and test details, ensuring that all necessary data is readily available for review. It outlines the specific welding processes used, such as manual, semiautomatic, or automatic, and details the materials involved, including base metal specifications and filler metal classifications. Additionally, the WPQR includes critical variables like the thickness of the materials, the positions in which the welder is qualified to work, and the type of shielding gas utilized during the welding process. The form also documents the results of mechanical tests and non-destructive examinations, confirming the quality and integrity of the welds produced. By certifying that all statements are accurate and that the welding was performed according to established standards, the WPQR serves as a reliable testament to a welder's capabilities, enhancing their credibility in the industry.

More PDF Templates

Notice of Intent to Lien Florida - The certificate of service section confirms that the notice was delivered properly, ensuring accountability.

What Do I Need to Get My Car Inspected in Pa - This form must be filled out separately for safety and emissions inspections.

Creating a Last Will and Testament is crucial for ensuring that your assets are allocated according to your wishes after you pass away; for more information on how to fill out this important document, visit https://smarttemplates.net/fillable-last-will-and-testament/.

Miscellaneous Information - Form 1099-MISC plays a significant role in the gig economy, serving many part-time workers.

Documents used along the form

The Welder Performance Qualification Record form is a crucial document that verifies a welder's skills and qualifications. To ensure a comprehensive understanding of a welder's capabilities, several other forms and documents are often used in conjunction with this record. Below is a list of these related documents, each serving an important role in the qualification process.

- Welding Procedure Specification (WPS): This document outlines the specific procedures and parameters for welding operations. It includes details such as the type of welding process, materials used, and joint design, ensuring consistency and quality in welding tasks.

- Certificate of Qualification: Issued after successful completion of performance tests, this certificate confirms that a welder has met specific standards set by industry codes. It serves as proof of competency in welding techniques.

- Non-Destructive Testing (NDT) Reports: These reports provide results from tests that assess the integrity of welds without causing damage. Common methods include ultrasonic testing and radiographic testing, helping to identify defects in welds.

- Visual Inspection Report: A simple yet essential document, this report records the findings of a visual inspection conducted on welds. It notes any visible defects and confirms whether the weld meets the required standards.

- Welder Identification Card: This card contains essential information about the welder, including their qualifications, certifications, and the types of welding they are authorized to perform. It acts as a quick reference for employers and inspectors.

- Test Results Log: This log records the results of various performance tests conducted on welders. It tracks their progress over time and provides a history of their qualifications and any re-certifications.

- USCIS I-864 Form: This document is essential for sponsoring family members applying for a green card, ensuring financial support and stability. For detailed information, visit OnlineLawDocs.com.

- Quality Control Plan: This document outlines the procedures and standards for ensuring quality in welding operations. It includes details on inspections, testing, and corrective actions to be taken in case of non-compliance.

- Welding Safety Plan: A critical document that addresses safety protocols and procedures during welding operations. It ensures that all personnel are aware of the hazards and safety measures associated with welding tasks.

- Equipment Calibration Records: These records ensure that all welding equipment is properly calibrated and functioning within specified parameters. Regular calibration helps maintain the quality and safety of welding operations.

In summary, these documents collectively support the welder qualification process, ensuring that welders possess the necessary skills and adhere to safety and quality standards. Each document plays a vital role in maintaining the integrity of welding practices and the safety of all involved.

Form Breakdown

| Fact Name | Details |

|---|---|

| Purpose | The Welder Performance Qualification Record form is used to document a welder's qualifications and test results. |

| Key Information | It includes details such as the welder’s name, test number, and specifications of the welding process. |

| Welding Processes | The form covers various welding processes, including manual, semiautomatic, mechanized, and automatic. |

| Qualification Range | It specifies the qualification range for different welding positions and thicknesses of materials. |

| Non-destructive Testing | Results from non-destructive examinations, such as radiographic testing, are included in the record. |

| Governing Laws | This form may be governed by AWS D1.1 and AWS B2.1 standards, depending on the specific application. |

More About Welder Performance Qualification Record

What is the purpose of the Welder Performance Qualification Record form?

The Welder Performance Qualification Record form serves as an official document that verifies a welder's skills and qualifications. It outlines the specific tests the welder has completed and the results achieved. This record is essential for ensuring that welders meet industry standards and are capable of performing welding tasks safely and effectively.

What information is included in the form?

The form includes several key pieces of information. It captures the welder's name, identification numbers, and the date of qualification. Additionally, it details the welding processes used, the materials involved, and the specific test results, including mechanical and non-destructive examination outcomes. This comprehensive data helps employers assess a welder's capabilities and compliance with industry standards.

How does the qualification process work?

The qualification process typically involves the welder completing a series of tests as outlined by specific codes or specifications, such as AWS D1.1. These tests assess various welding techniques and positions. After successfully completing the tests, the results are documented on the form. A certified welding inspector (CWI) must then review and sign the form to validate the qualifications.

What are the key components of the mechanical test results?

The mechanical test results section of the form includes the types of tests conducted, such as tensile or bend tests, along with their corresponding results. This section may also reference specific figures or standards that detail the performance expectations. Accurate documentation of these results is critical for verifying the welder's proficiency and ensuring compliance with relevant codes.

What role does non-destructive examination play in the qualification?

Non-destructive examination (NDE) is a crucial step in the qualification process. It assesses the integrity of the weld without damaging it. Common NDE methods include radiographic testing and visual inspections. The results of these examinations are documented in the form, providing additional evidence of the weld quality and the welder's skill level.

How long is the qualification valid, and how can it be renewed?

The validity of the qualification can vary based on industry standards and employer policies. Generally, qualifications may need to be renewed every six months to three years, depending on the specific requirements of the code or specification used. Renewal often involves re-testing or demonstrating ongoing competency through additional training or work experience.

Welder Performance Qualification Record: Usage Steps

Filling out the Welder Performance Qualification Record form is an important step in documenting a welder's skills and qualifications. This record serves as a formal acknowledgment of a welder's capabilities and the tests they have completed. To ensure accuracy and completeness, follow the steps outlined below.

- Welder's Information: Begin by entering the welder's name, ATF number, test number, and Social Security number in the designated fields. Also, include the date of the qualification test.

- Reference WPS Number: Fill in the Reference WPS (Welding Procedure Specification) number that corresponds to the test being conducted.

- Qualification Test Detail: Indicate the code or specification used for the qualification test. Specify the welding process and type, selecting from manual, semiautomatic, mechanized, or automatic options.

- Backing: Note whether backing was used or not, and if it was required.

- Base Metal Specification: Enter the specification or P/M number of the base metal, along with the thickness for groove and fillet welds, and the outside diameter for pipe or tubular materials.

- Filler Metal: Provide the specification number, classification number, filler metal number, and diameter of the filler metal used. Indicate if a consumable insert or penetration-enhancing flux was utilized.

- Deposited Weld Metal Thickness: Record the thickness of the deposited weld metal.

- Current and Polarity: Specify the type and polarity of the current used, along with the amperage range.

- Metal Transfer Mode: Indicate the metal transfer mode used (GMAW or FCAW) and detail the torch shielding gas type and flow rate.

- Root Shielding Gas: If applicable, provide the type and flow rate of the root shielding gas.

- Position(s): List the test positions (e.g., 1G, 2G) and the qualified positions (F, H, V, O, or All) for the welding performed.

- Vertical Progression: Specify the direction of vertical progression (uphill or downhill).

- Mechanical Test Results: Document the type and figure number of any mechanical tests conducted, along with the results.

- Non-Destructive Examination Results: Enter the radiographic results, including the report number and the name of the person who conducted the radiographic testing.

- Welding Witness: Note the name of the individual who witnessed the welding process.

- Visual Inspection: Indicate whether the visual inspection passed or failed, and provide reasons for any failures.

- Certification: Certify the accuracy of the information provided by signing the form, including the date qualified, ATF name and number, and the CWI number.